The future of handmade design

Driven by a love of craft and physical materials, the hands-on approach is enjoying an inspiring resurgence in the design world. Angharad Lewis investigates

Humans have been mechanising since prehistory, lightening our workloads, harnessing the forces of nature and performing feats beyond our physical abilities. Today, 100 years after the advent of modernism, technology dominates almost every aspect of life – and while this might seem at odds with handmade crafts, the evolution of both shares a trajectory.

Handmade processes and aesthetics have been returning to design for a decade or so. Mass-produced, machine-made and digitally crafted works have ceded some ground to the imperfect, tactile and subjective qualities of the handmade, and we have found ways to intervene by hand in the more alienating aspects of technology.

Creatively, we have reached something of a watershed. This return to humanistic and tactile sensibilities – a partial reversal of modernism’s sterility and machine-made aesthetic – sits alongside a new wave of technology that places control and ingenuity back in the hands of the individual. In graphics, visual styles based on screenprint, letterpress, papercraft, woodblock print, embroidery and hand-drawn lettering is now a common sight in branding and advertising. Once relegated to a crafty fringe, the handmade aesthetic is now mainstream, and ‘crafting’ pursuits have become big business with the recession bringing out a ‘make-do-and-mend’ spirit.

While this is very much a domestic pastime (think of quilting, baking and knitting), the movement is related to a shift in design practices in response to changes in consumer demand. Provenance, heritage and sustainability are now virtually mandatory aspects of brand development – qualities abundant in the craftsmanship associated with handmade design.

Stefan Sagmeister’s work has been at the vanguard of a humanistic approach to design for more than 15 years. His iconic 1999 poster for an AGIA lecture, for which he carved the textual details into his own body, could not be a more visceral rejection of mechanised design processes. Building, making and shaping components of the graphic end-product by hand is something Sagmeister has explored throughout his career. Why choose such a route?

“With the advent of modernism, everything became machine-made, be it in architecture, products or graphics,” he observes. “This made a lot of sense in the 1920s when there was a need to get rid of ornamentation in order to reflect the cultural climate. As this machine-made ‘objective’ direction has now been the status quo for almost 100 years, a more human, handmade, subjective, natural approach is the more effective way to communicate.”

Carving lettering into your own body is an extreme example, but typography and the visual rendering of words has been following an increasingly handmade path. The digitalisation of design revolutionised graphics in the 90s, and has since given rise to an endless proliferation of new fonts, some of which attempt to mimic handwriting. Meanwhile, the practice of writing by hand in everyday life has become scarce, with typing taking the place of pen and paper.

Digital degeneration

Dutch lettering artist Job Wouters, aka Letman, laments the decline of traditional practices in self-expression. “In a world where manual craft is supplanted more and more by digital technique,” says Wouters, “I find the universal and physical nature of handwriting fascinating. Most people acquire their penmanship in their early youth, but do not practice it until much later in life; the hand degenerates.” So too has the digitalisation of the design process affected its aesthetic development – to empowering effect, but also to the detriment of character.

Graphic artist Anthony Burrill seeks to revive the nature of the handmade creative process. “It doesn’t feel as satisfying just doing things on-screen any more,” he reflects. “I like the long process of making work physically.” Burrill works closely with long-standing collaborator Adams of Rye, a Sussex-based printer specialising in woodblock printing. It’s a process that has come to dominate Burrill’s practice, and while he still uses a computer to sketch layouts for his typographic prints, these are informed by his knowledge of Adams’ wood type collection. When placing type, variations emerge. The design must become responsive, with the layout, letter size and distribution of ink on paper partially determined by the process. Though full of imperfections, the final print is a beautiful manifestation of a narrative about making. “I like that aspect of it – that I’m not completely in control,” says Burrill.

Loss of control; letting the materials make some of the decisions; leaving things to chance and improvising in the final stages of production: these aspects of working by hand often make designers uncomfortable, but can yield the most interesting results. “It’s easy to make things look perfect on screen, so when things look handmade it intrigues people,” says Burrill.

Aslak Gurholt Rønsen of Norwegian design studio Yokoland echoes these sentiments. Any form of handmade process leads to a unique understanding of the design process, he observes: “Today, I spend most of my day in front of a screen. To do things by hand – drawing, painting, making a sculpture, or even constructing a piece of furniture – gives you an understanding of form, size, construction and colour, which is essential in design. Ultimately, how can you design anything without knowing how it’s produced?”

Ceding a degree of control over the end product is part of what enables handmade processes to reach their full potential. As German illustrator and set-designer Sarah Illenberger remarks, this relationship between maker and materials can also bring a freedom not available with digital tools: “The appeal of working by hand is that I feel I have more control over the piece I’m producing,” she says. “Especially when I’m working in 3D – I have the opportunity to view the object from all sides. Although there are programs to enable this, I prefer the real thing. It just feels more natural and satisfying.”

What emerges is that design practitioners are forging new ways to integrate manual and digital methods, using them at different stages of the design process, with one informing the other. Designers like Sam Winston – who spends hundreds of hours working by hand on his intricate paper sculptures and illustrations – do so to circumvent the homogenising influence of the computer. “I find it more rewarding to work with my hands on the page,” he explains. “It’s about still using your body in a physical way to directly create something. Even though a machine can create many things, the point of input is always the same – a keyboard and mouse, for example – so, as an experience goes, it can be very limited.”

Go hands-on first

Illustrator and weaver Hannah Waldron acknowledges the importance of digital design, but is careful about when she allows it into her work: “When you’re in the learning phase of a new craft it’s important to build up the knowledge in your hands before you can advance to computer-aided tools,” she says. “The hands are the most fundamental tools we have, and I really believe in the importance of the physical knowledge that the body develops. After three years of studying hand-weaving, I’m only now beginning to learn how to use the computer to assist and translate the process, which could lead to interesting applications.”

As our lives become increasingly digitalised, and we consume more images on-screen, the presence of handmade elements in a digital context brings the content back into our ‘real’ world and our tactile experiences. The notion of reality in photography has become blurred by CG, prompting a wave of photographers to go to great lengths to create something ‘real’ for their shoots. For Jay-Z’s 2009 album The Blueprint 3, photographer Dan Tobin Smith and his team built a room-sized sculpture from musical instruments and sound equipment. This was overpainted with three areas of red paint that, when the camera was in exactly the right spot, would show up as stripes across the centre of the image.

Building an image ‘in camera’ is central to how Tobin Smith works. “Still life photography means the image depends on the physical, from the angle of the lens to object, to the position and nature of the light,” he says. “Constructing what’s in-camera is just a part of that process or story. It’s natural to me to do it by hand.”

What takes months of planning and building by hand could be achieved in minutes on a computer, but the final image would lack integrity. It’s the story behind the making of such an image that captures the imaginations of viewers – the time-lapse making-of video for The Blueprint 3’s cover has been viewed over a million times online.

There is, then, a sense of honesty in the handmade process that can be absent in design created mechanically. Handmade elements set up a relationship with the viewer based on trust and shared experiences. Imperfections are natural, human, and signifiers of a narrative that discloses how an object has been made. “I think that working by hand contributes to the proximity between the work and its audience,” agrees Illenberger. “People sometimes feel my work could have been produced in their kitchen or at their desk. This closeness to reality results in the audience being able to relate to my images quickly. A computer-generated image always has something mystical and abstract to it.”

So what does the increased integration of the handmade into the creative process mean for the products being produced? And what future do handmade processes and aesthetics have in business and for consumers? Independent British fashion brand Tatty Devine enjoys global success from a 14-year dedication to the handmade. In 2012 the company’s turnover broke the £1m barrier, its founders Rosie Wolfenden and Harriet Vine were awarded MBEs for services to fashion, and the brand beat accessories giant Claire’s in a legal battle over copyright infringement. Supplying 300 retailers around the world, Tatty Devine designs and ‘micromanufactures’ all its products at workshops in London and Kent, where each piece is laser-cut from Perspex, then assembled and finished by hand.

Managing director Wolfenden is a passionate advocate of the value of the handmade in her products, and pinpoints its value in the relationship between her brand and its consumers: “Because of the special characteristics of the handmade, there tends to be mutual respect between the work and the audience. Customers often refer to Tatty Devine jewellery as art, they feel it embodies something special and has a sincerity.”

Meanwhile, if the human touch is absent from products, consumers are intervening to customise and ‘hack’ mass-manufactured items into something more personal that genuinely answers their needs. The website ikeahackers.net has been documenting people’s adaptations of Ikea furniture since 2006, with contributors submitting images of customised furniture, such as stools reconfigured into shelving or bookcases into desks. Such ‘design hacking’ happens when products or tools aren’t adequate for the user’s needs.

Hacked off

“Hacking is really just today’s name for the personal creative spirit that has always underpinned human ingenuity,” says writer Scott Burnham in a 2009 report about design hacking for the RSA. “The farmer reworking a piece of machinery to perform a different function, or the housewife cutting the bottom off a plastic bottle to make it into a scoop: hacking is our response when the resources at hand come up short. When this ethos is applied to our relationship with design, it has a more fundamental charge – a return to design as a direct response to real problems faced by real people.”

Hacking is at the heart of the story of Sugru, a material developed by RCA graduate Jane ni Dhulchaointigh that can be shaped by hand and adheres to almost any surface, setting in 24 hours to a flexible, durable form that can be used to fix and modify almost any object. Dhulchaointigh won the London Design Festival’s inaugural Design Entrepreneur award for her product.

Sugru’s success is partly down to its ingenious properties, and partly to the inventiveness of its users. There is a growing community of Sugru users (140,000 and counting), whose fixes and modifications with Sugru are documented – from repairing leaky hiking boots to making custom grips for cameras – on the Sugru blog. Recalling the product’s development from the earliest stages, Dhulchaointigh says: “I knew that, by tapping into people’s innate creativity, all kinds of products could be transformed and improved. I knew that we could adapt and improve almost anything mass-produced.”

In 2010 Time magazine listed Sugru alongside the iPad as one of the top 50 inventions of the year. As its inventor notes: “The iPad was number 34, Sugru was number 22.” It’s an inspiring story illustrating how handmade interventions have, for some time now, been re-gaining ground in the design innovation stakes.

Get the Creative Bloq Newsletter

Daily design news, reviews, how-tos and more, as picked by the editors.

Making by hand isn’t just about using archaic tools and materials: it can apply to technology too. But this is a fact we’re discouraged from believing by technology companies, which engender a sense of alienation from the inner workings of products, such as the smartphones we hold in our hands every day. These companies would rather sell a new model than see people fix or modify a broken or outmoded one. A London-based organisation called Technology Will Save Us wants to challenge this recent disconnection between technology and the handmade. It runs workshops and design-and-sell kits for products that people can make themselves, including a set of speakers, a DIY synthesiser and a solar-powered ‘thirsty-plant detector’.

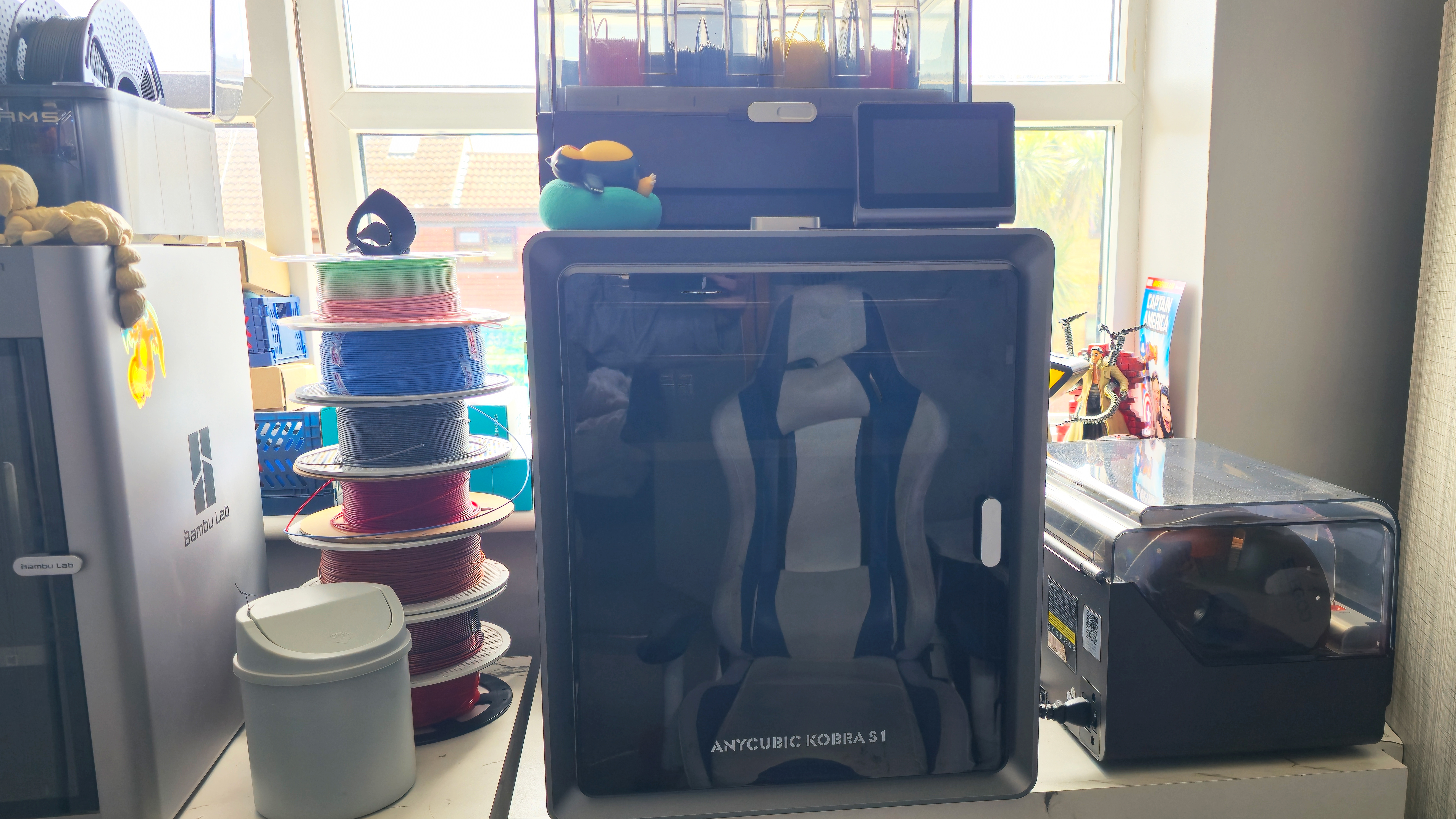

The next step on from hacking your existing products, of course, is to make the products yourself. This is about to become a real possibility with the advent of 3D printers, which are in the process of making it onto the high street and your kitchen table. Global stationery giant Staples announced recently that this year it will open in-store 3D printing services, starting in the Netherlands and Belgium before rolling the service out to other countries. This means that you’ll be able to upload your design to the Staples website and pick it up as a printed object at your local store, or have it shipped to you.

The possibilities for 3D printing are genuinely exciting, and for creative practitioners – as well as domestic users – it means the on-demand manufacture of components for any number of projects, from maquettes and models for pitches, to components for finished work. Creating prototypes is about to become easier and cheaper, and an elaborately designed project that might require testing in all manner of materials will now simply be extruded on a 3D printer. Desktop 3D printers like MakerBot’s Replicator will likely be found in most design studios in the next few years, and inside homes soon after. In the meantime, recent innovations like WobbleWorks’ 3Doodler are really putting the technology directly into the hands of users in the form of a pen that can ‘draw’ objects. While the $50 device doesn’t compare with the power of a 3D printer, it enables users to quickly create 3D objects on any surface, making the 3D printing process more affordable.

This brings the handmade very much into the here and now, with designers and image-makers increasingly taking a forward-looking stance, sharing a passion for the genuine innovation that comes from using handmade processes. An important collective goal emerged from the creatives that we spoke to: despite using time-honoured techniques, tools or equipment, there remains a desire to make end products that are very much centred in the present day. It isn’t about peddling nostalgia or making things look old. “That’s something I’m very conscious of,” Burrill insists. “Just because I’m making something using old techniques – I still want it to feel contemporary.” Wouters agrees: “I strive to give the human aspect of handwriting a place in my work without allowing it to become nostalgic.”

It’s the areas in which digital and analogue intersect that are the most experimental and innovative. The Open Source movement, which has given rise to increasingly accessible and adaptable ways of working digitally, has a lot in common with the impulse to work by hand. The ability to improvise, modify and adapt tools and processes equates to the resourcefulness developed via handmade working methods.

“All craftsmanship is founded on skill developed to a high degree,” says sociologist Richard Sennett in his book The Craftsman. Sennett counts computer programmers within his definition of craftsmen, particularly Linux programmers. “The experimental rhythm of problem-finding and solving makes the potter and the programmer part of the same tribe,” he adds.

While digital-aided design can create cheats and illusions, there is no substitute for the quality of the end product and the satisfaction in the making of a well-executed piece of handmade work by a practitioner who has mastered their craft, and this includes those working digitally. Likewise, the shortcuts implemented by machine-made production can be reversed by consumers’ interventions by hand.

The future of handmade is not simply about an aesthetic or a set of tools or practices, then, but a system of beliefs, or an ethic about ways of working that upholds quality, craftsmanship and innovation. The handmade in design is bound up with wider cultural changes relating to consumption. The hegemony of the mass-produced is compromised when we, as consumers, feel the need, and find ways to reverse it, by hacking its products into something more personal, rewarding and long-lived. Fundamentally, we are rediscovering our hands as tools, making us active participants in designing the future.

Thank you for reading 5 articles this month* Join now for unlimited access

Enjoy your first month for just £1 / $1 / €1

*Read 5 free articles per month without a subscription

Join now for unlimited access

Try first month for just £1 / $1 / €1

The Creative Bloq team is made up of a group of art and design enthusiasts, and has changed and evolved since Creative Bloq began back in 2012. The current website team consists of eight full-time members of staff: Editor Georgia Coggan, Deputy Editor Rosie Hilder, Ecommerce Editor Beren Neale, Senior News Editor Daniel Piper, Editor, Digital Art and 3D Ian Dean, Tech Reviews Editor Erlingur Einarsson, Ecommerce Writer Beth Nicholls and Staff Writer Natalie Fear, as well as a roster of freelancers from around the world. The ImagineFX magazine team also pitch in, ensuring that content from leading digital art publication ImagineFX is represented on Creative Bloq.