A quick intro to 3D printing for creatives

It might not be core to your creative business but can you really afford to overlook 3D printing?

3D printers are appearing at speed across the design industry and while it's difficult to see why the need for 3D printed objects in a web agency, for product designers, jewelers, architects and other creative professional access to a 3D printer makes perfect sense.

The technology has struck a balance between creative, tech and outright geek, unfortunately unless you're able to get stuck in and trial a few of the many printers available it's almost impossible to make a considered opinion as to which will suit you and your business.

If you have the chance then get along to a print show or maker place to see what's possible and how these machines work and could work for your business. If you can't then here we'll try to layout a guide to 3D print for creatives.

Making a choice should be easy as there are plenty of reviews out there, but these are mostly channeled by tech geeks who tend to look at a 3D printers ability to reproduce a Yoda or Hellboy head. This is fine if you're a model maker and want to print out figures, but if you're printing prototypes you need those prints to be as accurate as possible.

As a creative accuracy is imperative, yet many reviews will only lightly touch on accurate scale reproduction, materials, footprint and print size, and even when they do if you're unfamiliar with the process and technology it's often difficult to decypher what these mean, ultimately you need to know which 3D printer is going to work for your creative business with minimal fuss.

You need a printer that is reliable, can print different materials (albeit plastics) and reproduces your models and products accurately. Here are the first five features that you really need to consider before you go out and buy.

01. How much should you spend?

It's easy to be tempted by the variety of cheap 3D printers on the market and actually the print quality of many of these, even those at under £500, is very good. These printers however have generally been designed for the hobbyist, that not saying they're bad but they often need a bit of tinkering. This is a general statement but having tinkered with a few I'm confident in saying sub £500 is for the tinkering hobbyist not the working creative.

Get the Creative Bloq Newsletter

Daily design news, reviews, how-tos and more, as picked by the editors.

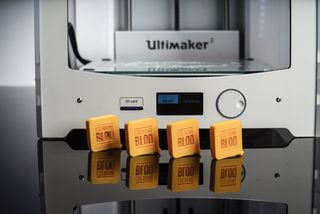

Around a £1000 is going to hit the mark with three manufactures having really upped the game in the last couple of years, Ultimaker, Lulzbot and Makerbot. All three have machines across the range that are extremely capable and reasonably priced at around £1000.

The Up! Plus 2 is a cheap 3D printer and available in high street stores. Print quality for the price is excellent and for a hobbyist makes perfect sense. But in a work environment where you just need your machines to work the need to recalibrate between prints makes it unpractical.

02. What are the different 3D printing processes?

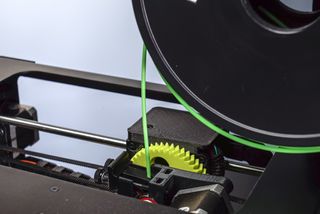

At present there are two that fit into the affordable bracket. The most popular of which is the additive process used by the likes of the Lulzbot. Put simply your 3D model is sliced into layers and then the printer prints these layers one on top of the other to create the physical model. The Lulzbot Mini is an example of a Additive Manufacturing (AM) printer.

The second process that has really only just started to become available is stereolithography… This is slightly more alien and works by firing UV light at resin and enables incredibly accurate prints. However compared to AM printing the process is a little more involved and messy.

03. What materials are being printed?

All sorts of materials can presently be printed but it very much depends on your printer. The Lulzbot Mini is a good example of a flexible machine able to print most plastics presently available; such as ABS, PLA and HIPS to name a few, it's open hardware design also means that addition heating elements and nozzles can be added to print further materials if needed.

The Ultimaker 2 also enables the printing of a variety of different materials but while the design of the Ultimaker Go and print quality for PLA filament is the same as the 2 the lack of a heated bed means that it is unable to print ABS.

A printer's ability to print different materials comes down to the heat that the hotend and nozzle are able to produce and the type of bed used by the printer as well as the print process.

04. How does it print a model and what do you use?

Once a model has been designed in your choice of 3D software for example Cinema 4D, that model is then exported out as an STL file. Both the Ultimaker and Lulzbot use the Cura software, but most printers will either come with their own software or use one of the many open source applications out there. The software will then slice the model loaded and in the case of Cura visually place it onto the virtual build platform so you can see how it will look.

Once you've checked your model, and depending on your printer you either click print to send the model through USB to the printer or load it onto a memory card to be manually loaded into the machine. The whole process really isn't too dissimilar to that of a conventional 2D printer.

05. Resolution is important but why?

Resolution is an important factor when it comes to print quality, at the moment in mid 2015 the majority of printers have a maximum layer height of 50 microns which is 0.05mm. This will give you a decent print but you will still be able to see the layering. Printers like the Ultimaker 2 reduce this height to 20 micron yet despite the improvement those layers are still visible.

To eliminate the sign of the layer a little finishing is always needed so at present don't expect the same high quality finish as you'd expect from injection moulding, however cost and convenience certainly makes 3D printing far more attractive to the creative user. If you're looking to prototype your creative projects the higher the resolution of the printer that you choose the better.

If you have questions about 3D printing then let us know in the comments…

Words: Alastair Jennings

Like this? Read these!

- 5 new animation trends for 2015 that will change everything

- How to approach colour matching with 3D printing

- Free graphic design software available to you right now!

Thank you for reading 5 articles this month* Join now for unlimited access

Enjoy your first month for just £1 / $1 / €1

*Read 5 free articles per month without a subscription

Join now for unlimited access

Try first month for just £1 / $1 / €1

The Creative Bloq team is made up of a group of design fans, and has changed and evolved since Creative Bloq began back in 2012. The current website team consists of eight full-time members of staff: Editor Georgia Coggan, Deputy Editor Rosie Hilder, Ecommerce Editor Beren Neale, Senior News Editor Daniel Piper, Editor, Digital Art and 3D Ian Dean, Tech Reviews Editor Erlingur Einarsson and Ecommerce Writer Beth Nicholls and Staff Writer Natalie Fear, as well as a roster of freelancers from around the world. The 3D World and ImagineFX magazine teams also pitch in, ensuring that content from 3D World and ImagineFX is represented on Creative Bloq.